Pneumatic transport can be defined as the transport of powdered, granular materials, or bulk goods, along a defined passage, using air or other fluid medium.

The pneumatic conveying system has the following characteristics:

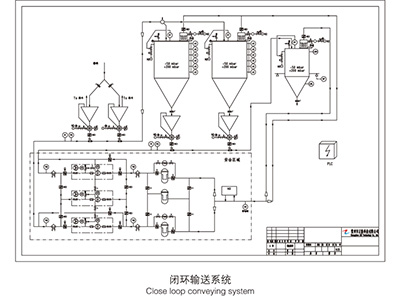

The delivery piping is flexible and not subject to path conditions. The closed conveying pipeline is not affected by the weather and surrounding conditions, and avoids moisture, fouling and foreign matter in the material;

The conveying process is dust-free and easy to achieve environmental protection requirements;

In the transportation process, a variety of process operations can be realized at the same time, such as mixing, crushing, grading, drying, cooling, dust removal, etc., and can be concentrated and dispersed for long distances. The equipment is simple, the operation and maintenance are convenient, the project investment and maintenance cost are small, the automation is easy, the required staff is small, and the manpower and management expenses are small.

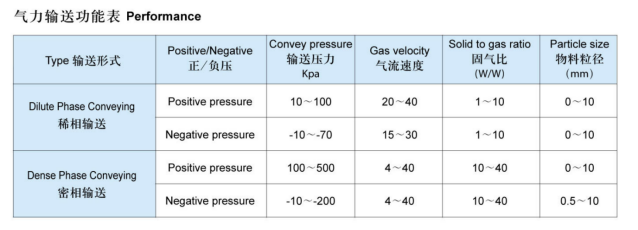

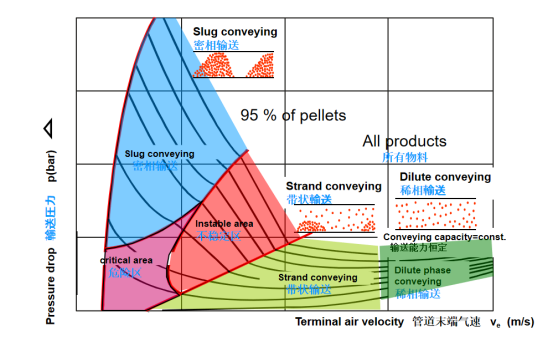

Pneumatic conveying form:

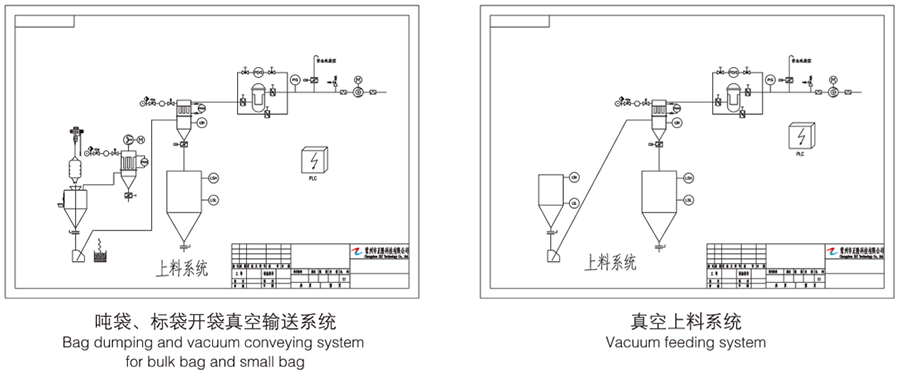

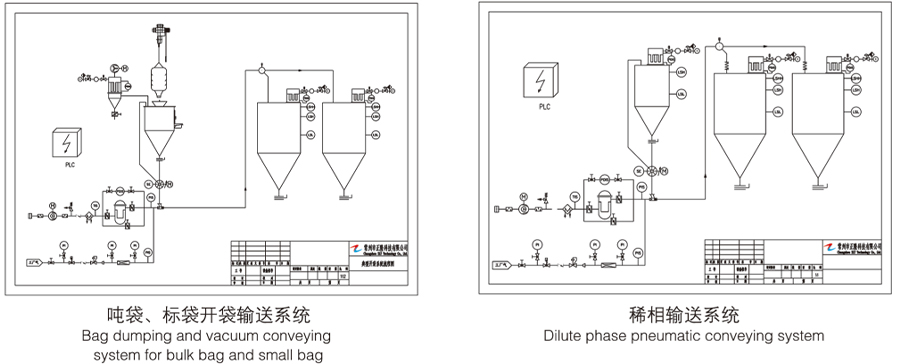

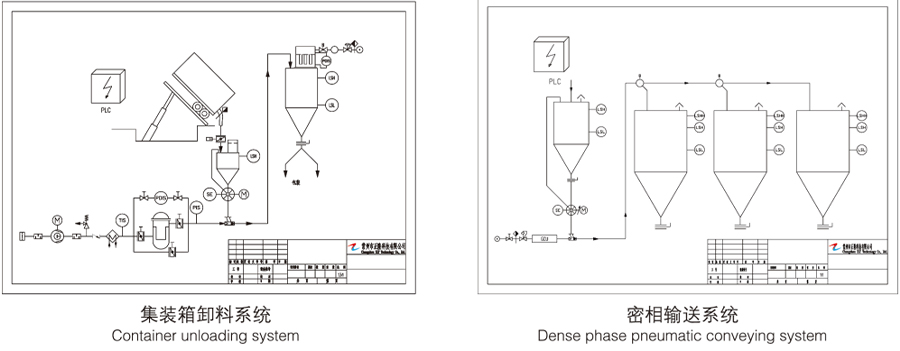

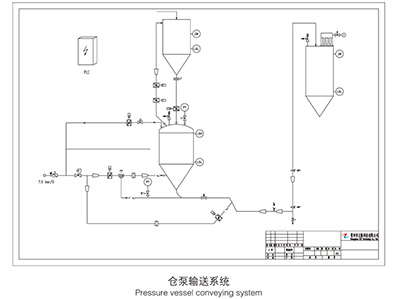

The pneumatic conveying system is divided into pressures in the conveying pipeline: positive pressure, negative pressure and positive pressure negative pressure combined system.

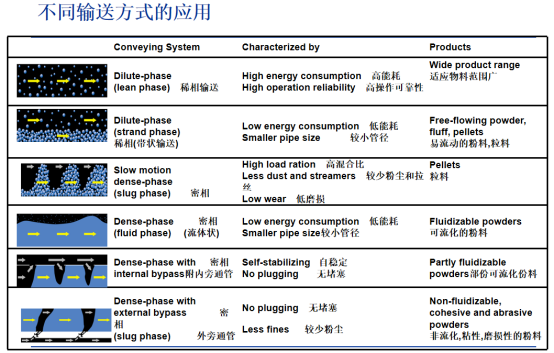

According to the material delivery status (solid-gas ratio): dilute phase, dense phase, semi-dense equal system.

Application of different conveying methods: