Introduction of centralized feeding and batching system

The whole plant automation design separates the raw material area from the production area and saves space.

The on-site working environment is clean and beautiful, improving environmental quality and reducing staff turnover.

When customers visit, they help to enhance the overall image of the company and get a good impression, thus increasing orders.

Establish a fast material selection station for raw materials, realize intelligent production through dedicated centralized feeding and batching software, and improve production efficiency.

Flexible production mode for a wide range of materials and products.

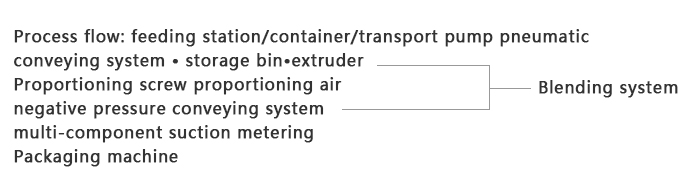

The centralized feeding and dosing system provided by CZL can be customized according to the process requirements and the characteristics of the materials. It can be used for single material batching system, multi-material batching system, mixed batching and other measurement methods. The precision can be 0.1-0.5. %.

Meet most of your company#39;s production needs, reduce manual participation, increase production efficiency, and meet flexible production.

Application areas: widely used in food, new energy, plastics, mining, chemicals, rubber, feed, etc.

Applicable materials: powder, granular, block, flake and liquid;

Here are our customers: